Digital Design, Millwork & Fabrication

We help take your projects all the way from ideation to realization.

We specialize in delivering turnkey fabrication services—from concept development through to final installation. Our work supports architects, designers, builders, and clients with complex or custom spatial and product needs.

Our capabilities include:

• Precision CNC cutting on two 5' x 10' (1524mm x 3048mm) 3-axis router tables with 9" Z-axis clearance

• Design development and technical documentation (CAD/CAM, shop drawings, and renderings)

• Custom millwork and furniture packages

• Rapid prototyping, jigs, and templating

• Component assembly, finishing, and on-site installation

• Project management and workflow coordination for seamless execution

With over 11 years of experience in CNC fabrication across Toronto, Canada, and the U.S., we’ve developed expertise in resolving geometric and scale constraints. This includes completing large-scale projects originally scoped for 5-axis machines by using intelligent sectioning, reorientation, and toolpath strategies.

In addition to CNC routing, we leverage a suite of professional fabrication tools and finishing equipment, allowing us to develop innovative, efficient, and high-quality solutions to complex design and production challenges.

Our selected millwork project builds: (more detailed project information below)

Applications we provide CNC services to:

furniture

As well as creating a line of furniture for home and office, we work with fine woodworkers to create parts, jigs, flatten table tops, and support wherever we can provide efficiencies within a craftsperson’s existing process of design and making.

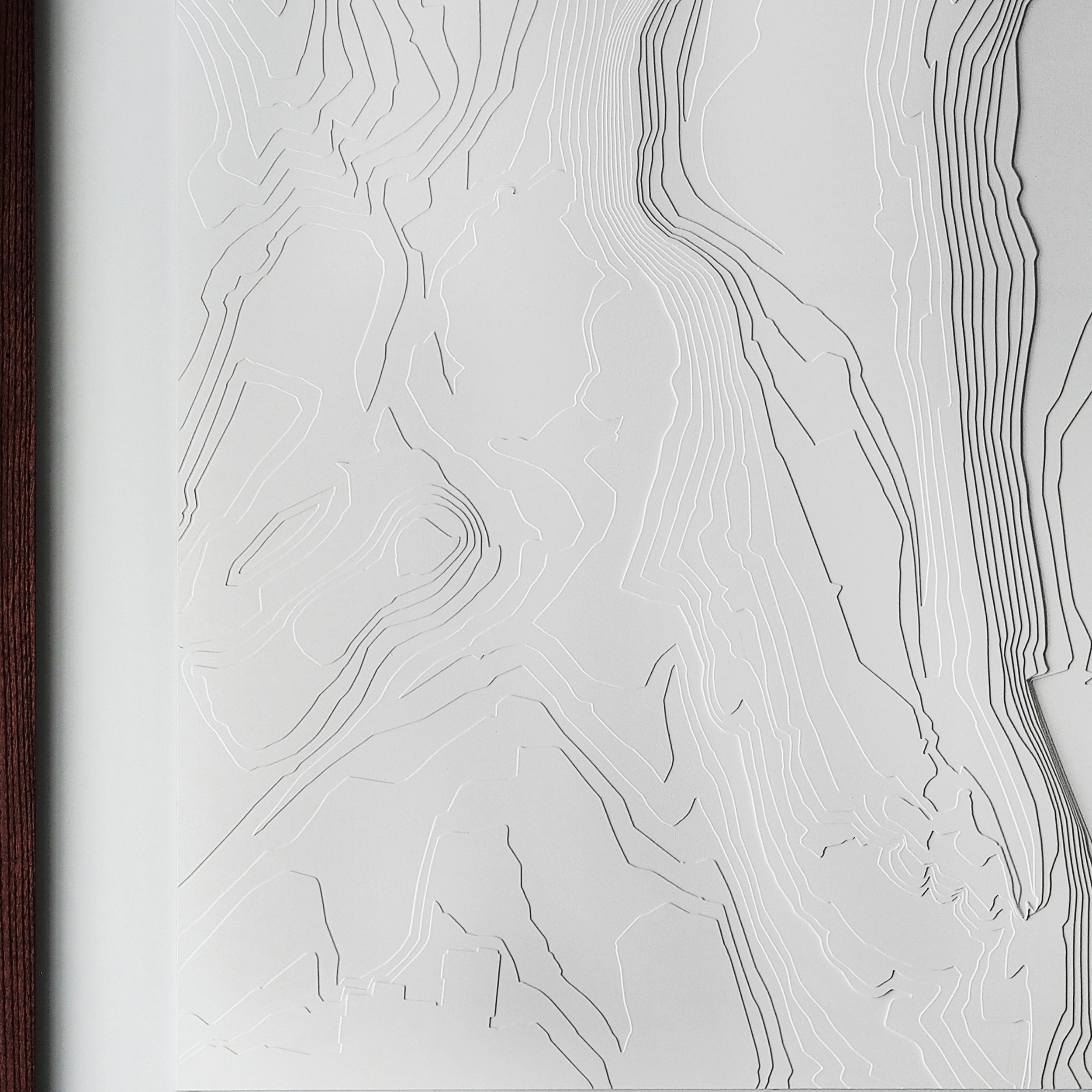

models

Architectural and topographical models, perfect for presentation and sales use or to install permanently for information or artwork. Use high density polyurethane foam, plywood, or solid timber.

film + theater

We build custom elements for stage and film sets and props.

interiors

A one-stop solution for your interior fit-out, we can design, fabricate, finish and install the whole project. We work with our partners to handle steel, glass and stone components and make sure all the pieces come together beautifully.

molds

Molds for fibreglass, plaster, concrete and resin applications. Typically from MDF or high density foams, we can offer a number of differing grades of finish to match budget and application.

architecture

Our experience in complex material assemblies helps manage the production and project management of facade elements, panel cladding and other architectural applications.

signage

We support both milling text and logos into surfaces or cutting out for installation on a secondary surface, we'll advise on what tooling you'll need, what it will look like, and make you a jig for installation.

heritage

We have been engaged a number of times to match trim in heritage restoration projects. From a supplied piece we measure, model and prototype before supplying the required lengths.

prototyping

Before projects begin production or final decisions are made we provide material, detail and design prototypes to convey the nature of the final outcome or to provide budget alternatives.